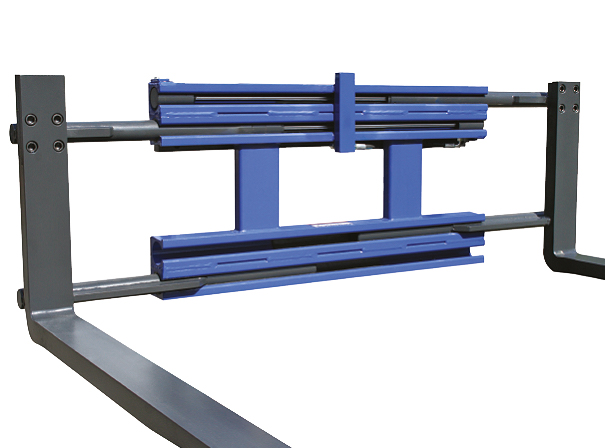

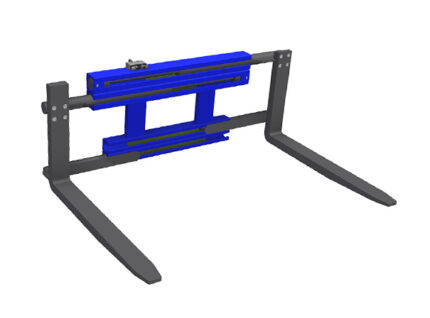

Clear view Fork Positioner FPN - version with or without integrated sideshift |

||||||||||

|

Series |

Load capacity kg at LSP mm |

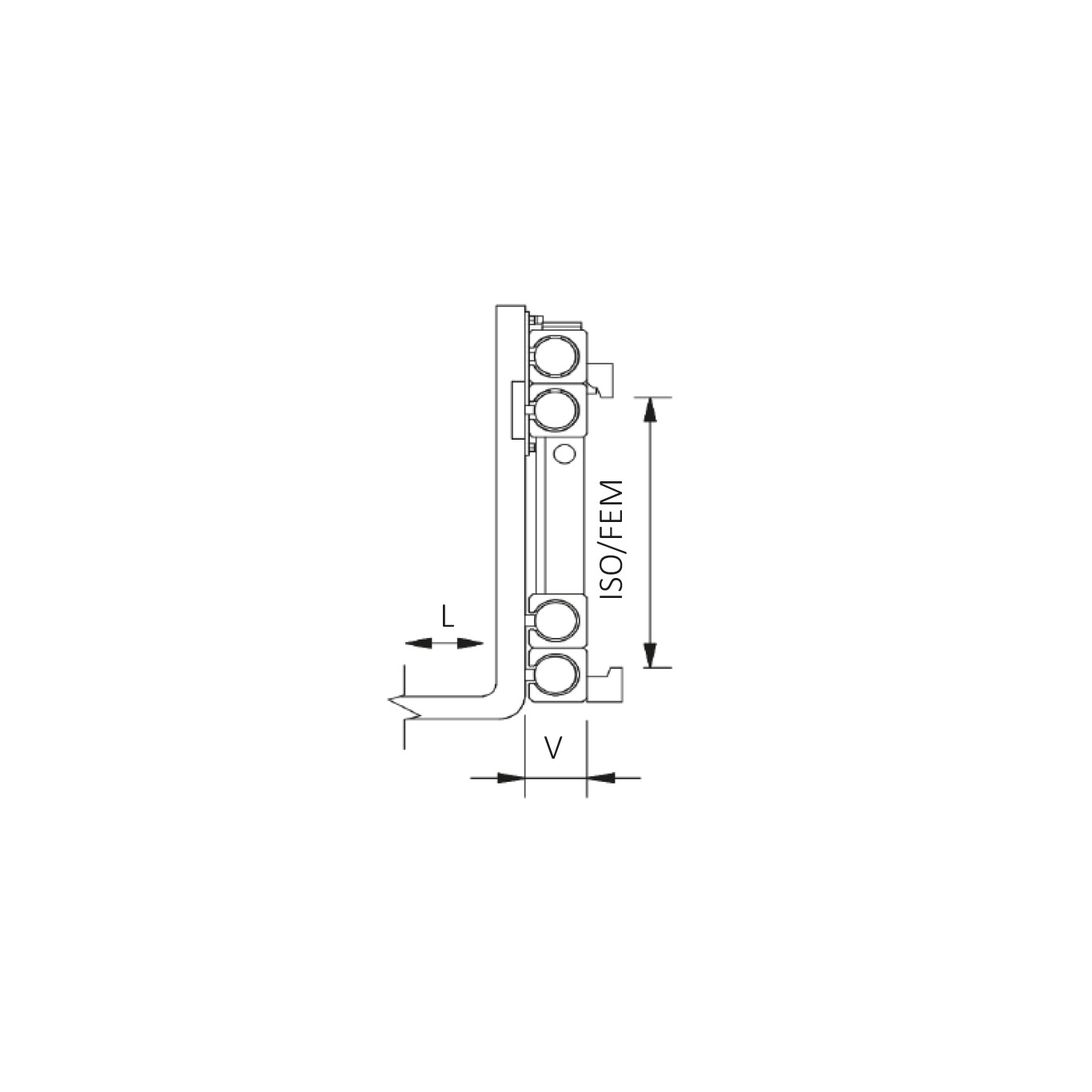

ISO/FEM |

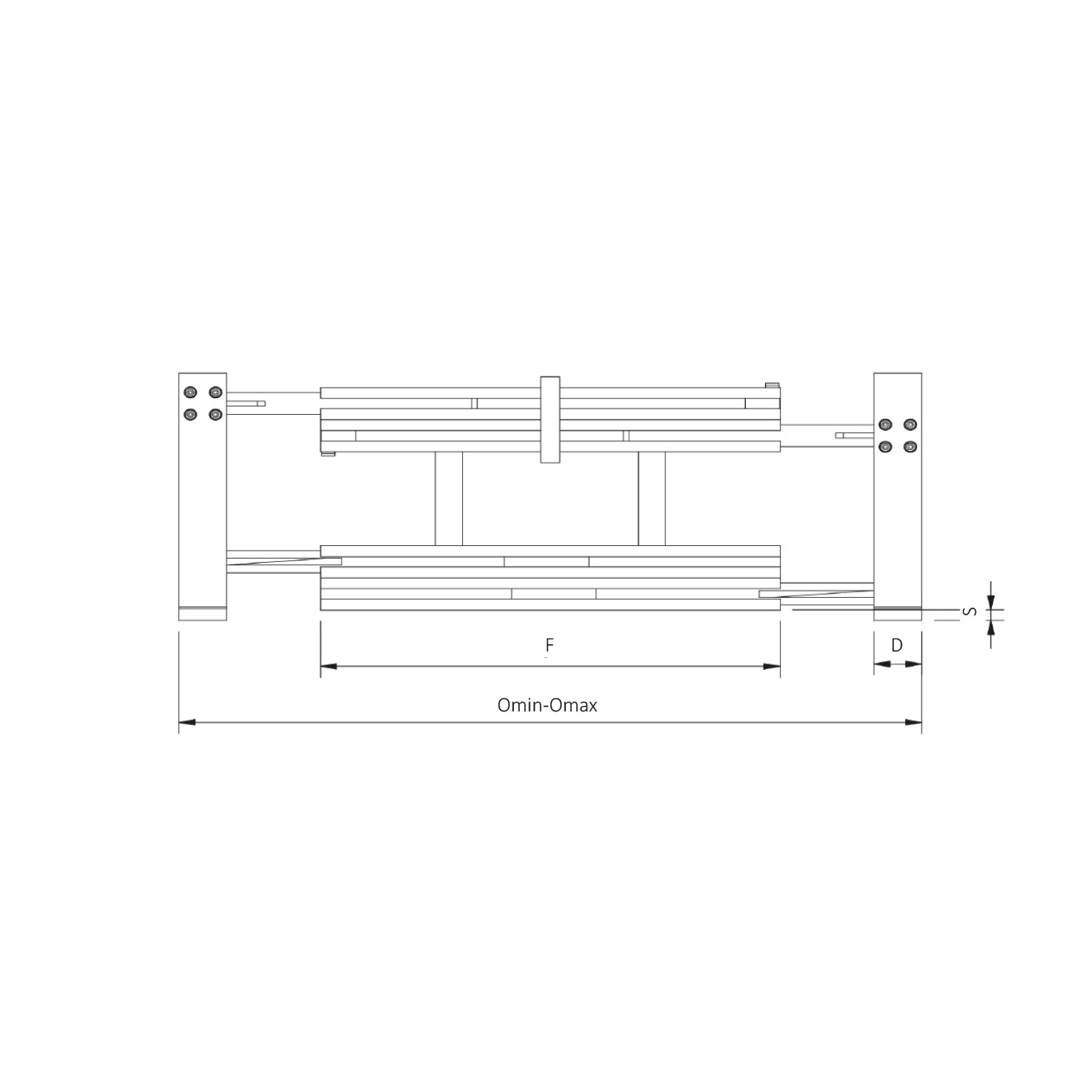

Width F mm |

Omin-Omax mm |

Cross section DxS mm |

V mm |

ESP mm |

Eig. wt. kg |

||

|

FPN 18 |

1800/500 |

II |

850 |

560-1440 |

100×45 |

80 |

240 |

245 |

||

|

FPN 18 |

1800/500 |

II |

950 |

560-1640 |

100×45 |

80 |

232 |

254 |

||

|

FPN 18 |

1800/500 |

II |

1050 |

560-1440 |

100×45 |

80 |

227 |

260 |

||

|

FPN 25 |

2500/500 |

II |

1100 |

560-1840 |

125×45 |

97 |

219 |

347 |

||

|

FPN 25 |

2500/500 |

II |

1150 |

560-1890 |

125×45 |

97 |

216 |

346 |

||

|

FPN 25 |

2500/500 |

II |

1200 |

560-1940 |

125×45 |

97 |

213 |

351 |

||

|

FPN 30 |

3000/500 |

III |

1150 |

560-1890 |

125×45 |

97 |

208 |

410 |

||

|

FPN 30 |

3000/500 |

III |

1200 |

560-1940 |

125×45 |

97 |

206 |

416 |

||

|

FPN 30 |

3000/500 |

III |

1250 |

560-1990 |

125×45 |

97 |

203 |

422 |

||

|

FPN 35 |

3500/500 |

III |

1150 |

560-1790 |

125×50 |

97 |

217 |

423 |

||

|

FPN 35 |

3500/500 |

III |

1200 |

560-1840 |

125×50 |

97 |

215 |

429 |

||

|

FPN 35 |

3500/500 |

III |

1250 |

560-1890 |

125×50 |

97 |

212 |

435 |

||

|

FPN 40 |

4000/500 |

III |

1200 |

560-1790 |

150×50 |

97 |

221 |

475 |

||

|

FPN 40 |

4000/500 |

III |

1300 |

560-1890 |

150×50 |

97 |

218 |

481 |

||

|

FPN 40 |

4000/500 |

III |

1400 |

560-1990 |

150×50 |

97 |

216 |

488 |

||

|

FPN 50 |

5000/500 |

III |

1250 |

560-1790 |

150×50 |

124 |

204 |

580 |

||

|

FPN 50 |

5000/500 |

III |

1350 |

560-1890 |

150×50 |

124 |

202 |

588 |

||

|

FPN 50 |

5000/500 |

III |

1450 |

560-1990 |

150×50 |

124 |

200 |

596 |

||

|

FPN 50 |

5000/600 |

IV |

1300 |

560-1840 |

150×60 |

129 |

197 |

702 |

||

|

FPN 50 |

5000/600 |

IV |

1400 |

560-1950 |

150×60 |

129 |

194 |

722 |

||

|

FPN 50 |

5000/600 |

IV |

1500 |

560-2050 |

150×60 |

129 |

191 |

742 |

||

|

FPN 60 |

6000/600 |

IV |

1400 |

560-1950 |

150×60 |

129 |

193 |

727 |

||

|

FPN 60 |

6000/600 |

IV |

1500 |

560-2050 |

150×60 |

129 |

189 |

747 |

||

|

FPN 60 |

6000/600 |

IV |

1600 |

560-2150 |

150×60 |

129 |

185 |

767 |

||

Clear view Fork Positioner FPN - version with separate sideshift |

||||||||||

|

Series |

Load capacity kg at LSP mm |

ISO/FEM |

Width F mm |

Omin-Omax mm |

Cross section DxS mm |

V mm |

ESP mm |

Eig. wt. kg |

||

|

FPN 18 |

1800/500 |

II |

850 |

560-1440 |

100×45 |

97 |

237 |

266 |

||

|

FPN 18 |

1800/500 |

II |

950 |

560-1640 |

100×45 |

97 |

231 |

274 |

||

|

FPN 18 |

1800/500 |

II |

1050 |

560-1440 |

100×45 |

97 |

226 |

282 |

||

|

FPN 25 |

2500/500 |

II |

1100 |

560-1840 |

125×45 |

114 |

226 |

363 |

||

|

FPN 25 |

2500/500 |

II |

1150 |

560-1890 |

125×45 |

114 |

223 |

368 |

||

|

FPN 25 |

2500/500 |

II |

1200 |

560-1940 |

125×45 |

114 |

221 |

374 |

||

|

FPN 30 |

3000/500 |

III |

1150 |

560-1890 |

125×45 |

117 |

215 |

442 |

||

|

FPN 30 |

3000/500 |

III |

1200 |

560-1940 |

125×45 |

117 |

213 |

449 |

||

|

FPN 30 |

3000/500 |

III |

1250 |

560-1990 |

125×45 |

117 |

211 |

455 |

||

|

FPN 35 |

3500/500 |

III |

1150 |

560-1790 |

125×50 |

122 |

223 |

458 |

||

|

FPN 35 |

3500/500 |

III |

1200 |

560-1840 |

125×50 |

122 |

213 |

450 |

||

|

FPN 35 |

3500/500 |

III |

1250 |

560-1890 |

125×50 |

122 |

211 |

457 |

||

|

FPN 40 |

4000/500 |

III |

1200 |

560-1790 |

150×50 |

122 |

228 |

512 |

||

|

FPN 40 |

4000/500 |

III |

1300 |

560-1890 |

150×50 |

122 |

226 |

518 |

||

|

FPN 40 |

4000/500 |

III |

1400 |

560-1990 |

150×50 |

122 |

224 |

525 |

||

|

FPN 50 |

5000/500 |

III |

1250 |

560-1790 |

150×50 |

154 |

217 |

627 | ||

|

FPN 50 |

5000/500 |

III |

1350 |

560-1890 |

150×50 |

154 |

215 |

635 |

||

|

FPN 50 |

5000/500 |

III |

1450 |

560-1990 |

150×50 |

154 |

214 |

643 |

||

|

FPN 50 |

5000/600 |

IV |

1300 |

560-1840 |

150×60 |

169 |

216 |

774 |

||

|

FPN 50 |

5000/600 |

IV |

1400 |

560-1950 |

150×60 |

169 |

213 |

794 |

||

|

FPN 50 |

5000/600 |

IV |

1500 |

560-2050 |

150×60 |

169 |

210 |

814 |

||

|

FPN 60 |

6000/600 |

IV |

1400 |

560-1950 |

150×60 |

169 |

211 |

809 |

||

|

FPN 60 |

6000/600 |

IV |

1500 |

560-2050 |

150×60 |

169 |

208 |

828 |

||

|

FPN 60 |

6000/600 |

IV |

1600 |

560-2150 |

150×60 |

169 |

206 |

848 |

||

- Sideshift separate (type -S): with separate cylinder 100 mm to the left and right at each fork position (from FPN 50: 125+125 mm).

- Different widths, opening ranges or a suspension integrated in the mast (FPNI series) on request.

- Painting base body blue (RAL 5002), forks and sliding arms gray (RAL 7021).

- Not suitable for stapling

Guideline values for residual load capacity of forklift trucks (front loader, LSP at 500 mm, without sideshift) |

|

|

||||||||||

|

Fork Positioner FPN |

|

FPN 18 |

FPN 18 |

FPN 25 |

FPN 25 |

FPN 30 |

FPN 35 |

FPN 40 |

FPN 50 |

FPN 50 |

FPN 50 |

FPN 60 |

|

Load bearing stacker |

kg |

1600 |

1800 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000/500 |

5000/600 |

6000 |

|

X (assumed) |

mm |

350 |

375 |

450 |

450 |

450 |

500 |

500 |

560 |

560 |

560 |

560 |

|

LSP = 500 mm |

kg |

1425 |

1600 |

1675 |

2150 |

2625 |

3100 |

3500 |

3675 |

4125 |

- |

- |

|

LSP = 600 mm |

kg |

1275 |

1450 |

1525 |

1975 |

2400 |

2800 |

3200 |

3380 |

3800 |

4120 |

4950 |

|

LSP = 700 mm |

kg |

1150 |

1325 |

1400 |

1800 |

2200 |

2600 |

2950 |

3125 |

3500 |

3800 |

4600 |

The final residual capacity of the forklift can only be confirmed by the forklift supplier.